Exercise 08 - Size optimization for continua¶

Task 1 - Book shelf¶

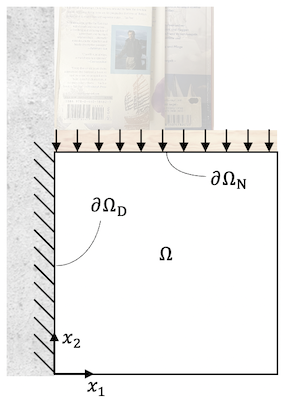

Let us consider a bookshelf that needs a support structure. The design domain is given by a unit square $x \in [0, 1]^2$ and a maximum thickness $d_{max}=0.1$. The left boundary of the domain $\partial \Omega_D$ is fixed to the wall and the top boundary $\partial \Omega_N$ is loaded with a uniform line load representing the weight of books.

from math import sqrt

import torch

from torchfem import Planar

from torchfem.materials import IsotropicElasticityPlaneStress

from torchfem.mesh import rect_quad

from tqdm import tqdm

torch.set_default_dtype(torch.double)

The following code creates a planar FEM object called square. It uses a constant thickness of $d=0.1$ for the entire domain, forces $f(\mathbf{x}) = 1.0/N, \mathbf{x} \in \partial \Omega_N$ and the material parameters $E=1000.0, \nu=0.3$.

# Create nodes and elements for a rectangular mesh

N = 10

L = 1.0

nodes, elements = rect_quad(Nx=N + 1, Ny=N + 1, Lx=L, Ly=L)

# Define Material

material = IsotropicElasticityPlaneStress(E=1000.0, nu=0.3)

# Create model

square = Planar(nodes, elements, material)

# Define masks for boundary conditions

top = nodes[:, 1] == L

left = nodes[:, 0] == 0.0

right = nodes[:, 0] == L

tip = top & right

# Load at top

square.forces[top, 1] = -1.0 / N

square.forces[tip, 1] = -0.5 / N

# Constrained displacement at left end

square.constraints[left, :] = True

# Thickness

square.thickness[:] = 0.1

# Solve the system

u, f, sigma, F, state = square.solve()

# Compute von Mises stress

mises = torch.sqrt(

sigma[:, 0, 0] ** 2

- sigma[:, 0, 0] * sigma[:, 1, 1]

+ sigma[:, 1, 1] ** 2

+ 3 * sigma[:, 1, 0] ** 2

)

# Plot the result

square.plot(

u=u,

element_property=mises,

cmap="viridis",

title="von Mises stress",

colorbar=True,

)

To save material, the bookshelf should use only 50% of that given design space, while being as stiff as possible to support many books. We want to achieve this by a variable thickness distribution of the component.

You are provided with a function that performs root finding with the bisection method from a previous exercise. Now, you should implement a size optimization algorithm with MMA in a function named optimize(fem, d_0, d_min, d_max, V_0, iter=15) that takes the FEM model fem, the initial thickness distribution d_0, the minimum and maximum thickness distributions d_min, d_max, the volume constraint, and the maximum iteration count iter with a default value of 15.

a) Write a helper function compute_areas(truss) that computes the areas of the elements in the FEM object truss. The function should return a torch array with the areas of the elements.

Hints: The variable nodes has the shape (Mx4x2), i.e the four ($x_1$, $x_2$) coordinates of the nodes of each element $j \in [0...M-1]$. The loop iterates over all integration points with weights w and positions q.

b) Add code that modifies the thickness according to the current design variables and solves the FEM problem in each iteration. Hint: You can overwrite fem.thickness to set the thickness of the FEM object.

c) Add code to computes the strain energy w.

d) Add the analytical solution for $d^*$. Hint: This is analogous to the truss problem.

e) Add the analytical solution for the gradient of the dual function w.r.t. $\mu$. Hint: This is analogous to the truss problem.

f) Solve the dual problem with bisection.

g) Compute current optimal point with dual solution and append it to solutions.

def bisection(f, a, b, max_iter=50, tol=1e-10):

# Bisection method always finds a root, even with highly non-linear grad

i = 0

while (b - a) > tol:

c = (a + b) / 2.0

if i > max_iter:

raise Exception(f"Bisection did not converge in {max_iter} iterations.")

if f(a) * f(c) > 0:

a = c

else:

b = c

i += 1

return c

def compute_areas(model):

areas = torch.zeros((model.n_elem))

nodes = model.nodes[model.elements, :]

for w, q in zip(model.etype.iweights(), model.etype.ipoints()):

# Compute the Jacobian

J = model.etype.B(q) @ nodes

# Compute the determinant of the Jacobian

detJ = torch.linalg.det(J)

# Add the contribution of this integration point to the area

areas += w * detJ

return areas

def optimize(fem, d_0, d_min, d_max, V_0, iter=15):

# Compute stiffness matrix without thickness factor

k0 = torch.einsum("i,ijk->ijk", 1.0 / fem.thickness, fem.k0())

# List for thickness results and lower asymptotes

d = [d_0]

L = []

# Element-wise areas

areas = compute_areas(fem)

# MMA parameter

s = 0.7

# Check if there is a feasible solution before starting iteration

if torch.inner(d_min, areas) > V_0:

raise Exception("d_min is not compatible with V_0.")

# Iterate solutions

for k in tqdm(range(iter)):

# Compute lower asymptote

if k <= 1:

L_k = d[k] - s * (d_max - d_min)

else:

L_k = torch.zeros_like(L[k - 1])

osci = (d[k] - d[k - 1]) * (d[k - 1] - d[k - 2]) < 0.0

L_k[osci] = d[k][osci] - s * (d[k - 1][osci] - L[k - 1][osci])

L_k[~osci] = d[k][~osci] - 1 / sqrt(s) * (d[k - 1][~osci] - L[k - 1][~osci])

L.append(L_k)

# Compute lower move limit in this step

d_min_k = torch.max(d_min, 0.9 * L[k] + 0.1 * d[k])

# Solve the problem at d_k

fem.thickness = d[k]

u_k, _, _, _, _ = fem.solve()

# Compute strain energy density

disp = u_k[fem.elements, :].reshape(fem.n_elem, -1)

w_k = 0.5 * torch.einsum("...i,...ij,...j", disp, k0, disp)

# Analytical solution

def d_star(mu):

d_hat = L[k] + torch.sqrt((2.0 * w_k * (L[k] - d[k]) ** 2) / (mu * areas))

return torch.clamp(d_hat, d_min_k, d_max)

# Analytical gradient

def grad(mu):

return torch.dot(d_star(mu), areas) - V_0

# Solve dual problem

mu_star = bisection(grad, 1e-10, 100.0)

# Compute current optimal point with dual solution

d.append(d_star(mu_star))

return d

h) Now run the optimization with $d_0=0.05, d_{min}=0.001, d_{max}=0.1$ and a volume constraint $V_0=50\%$ of the maximum design volume.

# Initial thickness, minimum thickness, maximum thickness

d_0 = 0.05 * torch.ones(len(square.elements))

d_min = 0.001 * torch.ones_like(d_0)

d_max = 0.1 * torch.ones_like(d_0)

# Initial volume (50% of maximum design volume)

areas = compute_areas(square)

V0 = 0.5 * torch.inner(d_max, areas)

# Optimize and visualize results

d_opt = optimize(square, d_0, d_min, d_max, V0, iter=30)

square.plot(element_property=d_opt[-1], cmap="gray_r")

100%|██████████| 30/30 [00:00<00:00, 112.23it/s]

i) Plot the evolution of design variables vs. iterations. What does the graph tell you?

import matplotlib.pyplot as plt

plt.plot(torch.stack(d_opt).detach())

plt.xlabel("Iteration")

plt.ylabel("Values $d_i$")

plt.grid()

j) How do you interpret the design? Decide which manufacturing process you would like to use and use a CAD software to create a design based on your optimization.

centers = square.nodes[square.elements].mean(dim=1)

plt.contourf(

centers[:, 0].reshape(N, N),

centers[:, 1].reshape(N, N),

d_opt[-1].reshape(N, N),

levels=4,

cmap="coolwarm",

)

plt.colorbar(label="Thickness")

plt.axis("equal")

plt.axis("off")

plt.show()